NEWS

Castem Technology Laboratory Wins Top Prize at U.S. Casting Contest

LATEST NEWS

Castem Technology Laboratory (CTL), based in California, USA, has won the Overall First Place Award at the casting contest held in conjunction with the Investment Casting Institute (ICI) 2025 Technical Conference & Expo, which took place from September 28 to October 1 in Pennsylvania.

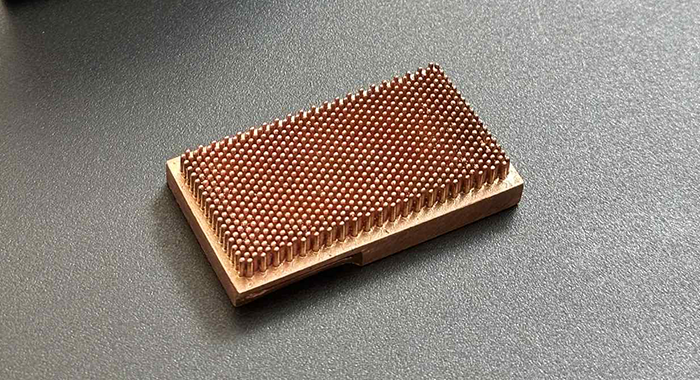

The award-winning entry, a Pure Copper Heat Sink, measures 52 × 28 × 13 mm and weighs 64 g. By leveraging advanced and innovative investment casting techniques, CTL successfully realized an extremely complex geometry featuring ultra-thin walls and a large number of fine pins, all produced with exceptional dimensional accuracy.

The ICI Technical Conference & Expo is the largest annual gathering of professionals in the precision casting industry in North America. Among seven finalist works, CTL’s entry was selected as the top award through voting by conference participants.

Details of the award-winning piece are outlined below.

Name: Pure Copper Heat Sink

Dimensions: 52 x 28 x 13mm

Weight: 64 grams

Alloy: Pure Copper

CTL developed a compact pure copper immersed heat sink to meet the demanding thermal management needs of the electronics industry. Measuring only 52 × 28 × 13 mm and weighing 64 grams, the part functions as a cooling chamber, transferring heat from internal electronic components to circulating coolant. The challenge was to produce a hermetic, leak-proof enclosure with ultra-thin walls and intricate rows of micro posts—features not achievable through traditional machining or fabrication.

By using a vacuum-pressure-assisted solid mold process with 3D-printed sacrificial patterns, they achieved the fine detail and dimensional accuracy required. Investment casting in pure copper would have been a multi-piece assembly, but this process maximized thermal performance and productivity while minimizing assembly steps, replacing what would have been a longer fabrication with a single integrated part to fit seamlessly into housing with tight ±0.5 mm tolerances, enabling the part to fit seamlessly into housing and pass high-benchmark cooling tests.

This innovation demonstrates how investment casting enables compact, high-precision, and functional components that support next-generation electronics.