MEDICAL PROJECT

We are expanding the medical business and promoting research and development as a close partner for our customers.

WHY MEDICAL?

Manufacturing That Cares For Users

In 1970, Castem started business from a small factory that handcrafts confectionery equipment by casting technology. Since we started our business, we have been taking on works that other companies do not want to do, such as small lots, difficult materials, and complicated shapes. As a result of working with flexible ideas and energy, we have built several unique technologies.

Castem, which started the business from handcrafting machine tools, still has the same belief that we want to be the power of “people who create something.” And now, Castem has started the medical equipment business by ultra-precision molding technology with the backbone of lost wax and metal injection. We have been developing some projects with medical institutions and medical equipment manufacturers.

In this medical project, we work on research and development in the medical field by making full use of the technology that Castem has accumulated over many years and the latest equipment.

Castem, which started the business from handcrafting machine tools, still has the same belief that we want to be the power of “people who create something.” And now, Castem has started the medical equipment business by ultra-precision molding technology with the backbone of lost wax and metal injection. We have been developing some projects with medical institutions and medical equipment manufacturers.

In this medical project, we work on research and development in the medical field by making full use of the technology that Castem has accumulated over many years and the latest equipment.

What We Can Do for The Medical Field

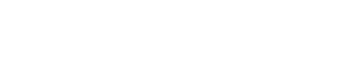

01Industrial CT Scanner MCT225

02KOKEN KOACH C900

03Android II Ultra High-Precision High-Speed Micro Machining Center

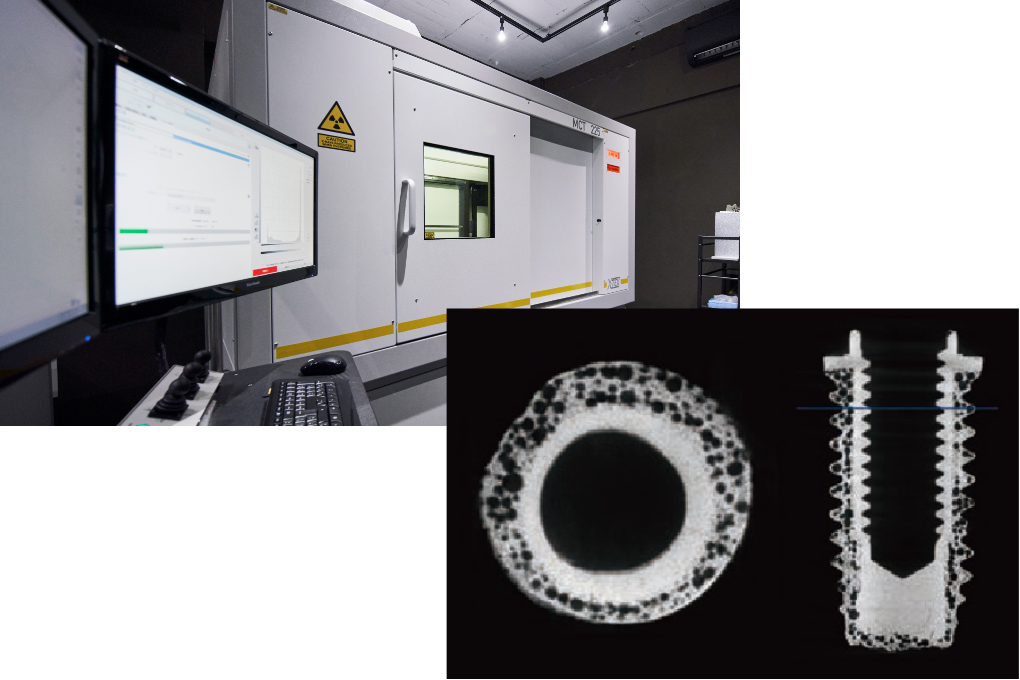

04High-end 3D Printer Stratasys J750

Industrial CT Scanner MCT225

It is possible to make high precision measurements and analysis, take cross-sectional images and videos, output 3D video, and digitalize the 3D data (OBJ, STL) with high resolution by metrology CT scanning system “MCT225” of Nikon Instec (Nikon Solutions Co., Ltd.)

KOKEN KOACH C900

“KOKEN KOACH C900” is an open clean air system that can create an ISO Class 1 clean air environment in less than a minute after the system starts up. We have introduced it to the final inspection and packing workplace to improve the manufacturing environment for medical equipment.

Android II Ultra High-Precision High-Speed Micro Machining Center

We have worked on research of high precision mold machining with “Android II Ultra High-Precision High-Speed Micro Machining Center” which can process in a unit of a micrometer.

High-end 3D Printer Stratasys J750

“Stratasys J750” is a multi-material full-color 3D printer that can output six types of different materials at once. Also, it is possible to express more than 360,000 vivid colors. It enables us to produce a prototype equivalent to the finished product in the shortest time by mixing transparent materials and rubber-like resins.

ISO13485:2016

Certified in October 2019

Certified in October 2019

Manufacture of Attachment Parts for Orthodontics by MIM

The Scope of Certification: Headquarters Factory (Hiroshima Prefecture), Kita Kanto Branch (Chiba Prefecture)

ISO13485 is an international standard for establishing “a system for ensuring stable medical equipment quality”. Since medical equipment directly affects human life and health, it is necessary to maintain quality and safety. We can obtain “certification” from the certification authority if we are confirmed as an organization that establishes a system that meets the requirements. This "certification" guarantees the ease of mind and trust of our customers.

COLLABORATION Japan Agency for Medical Research and Development

“Research on Development of New Medical Devices”

A Program of Osaka University Hospital

A Program of Osaka University Hospital

“Research on Development of New Medical Devices” is a subsidized project of the Japan Agency for Medical Research and Development, which aims to improve the environment and system to create domestically-produced medical equipment with international competitiveness. We collaborate with Osaka University Hospital and promote the development of human resources and collaborative research for the development of new medical devices.

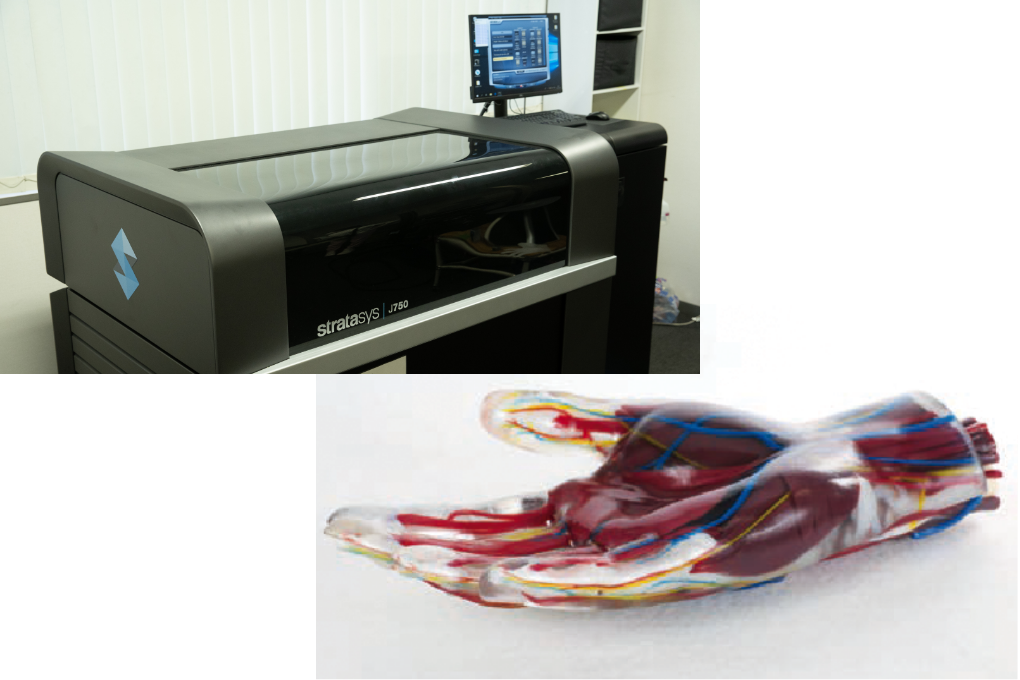

COLLABORATION Conclusion of the Comprehensive Partnership Agreement with Kyoto University of Advanced Science

We have concluded a comprehensive partnership agreement with the Kyoto University of Advanced Science and have been promoting collaborative research and development in the medical field by using various equipment in the university. “Photonic Professional GT2” is a high-resolution 3D printer that can model in a unit of a nanometer. “Y.Cheetah” is a CT scanner that can generate 2D / 3D images with extremely high resolution at high speed. “Speedy 400” is a laser engraver that can process with high precision at high speed.

Photonic Professional GT2

CT scanner "Y.Cheetah"

Laser engraver "Speedy 400"