SUBMICRON 3D PRINTING

First 3D modeling service in a unit of micrometer in Japan

The world’s smallest modeling service

We provide a service specialized in the prototyping of microlenses, diffractive optical elements, microneedles, and MEMS.

QUALITY

Possible to handle from one prototype without molds and cutting.

FREEDOM

Possible to model from JPY 50,000 per each time.

SHORT TERM

Possible to deliver the product in three weeks. Also, we can handle it without 3D data. (*Additional costs may be incurred in this case.)

ACHIEVEMENTS

Possible to check the shape with an optical microscope and electron microscope. (*Additional costs may be incurred for dimensional measurement.)

ACHIEVEMENTS

Possible to make it have electrical conductivity by a dry plating method (gold, platinum).

Examples of Proposals

01

Micro-optics

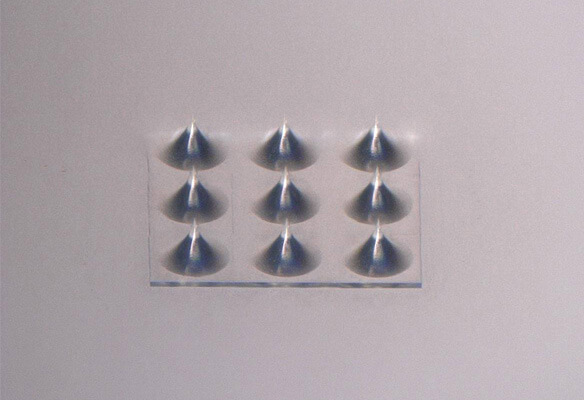

Hemispherical microlenses with a smooth surface

02

Biomedical engineering

Microneedle arrays with sharp points

03

Micro rapid prototyping

Conductive plugs (Method: sputtering/ Material: platinum)

04

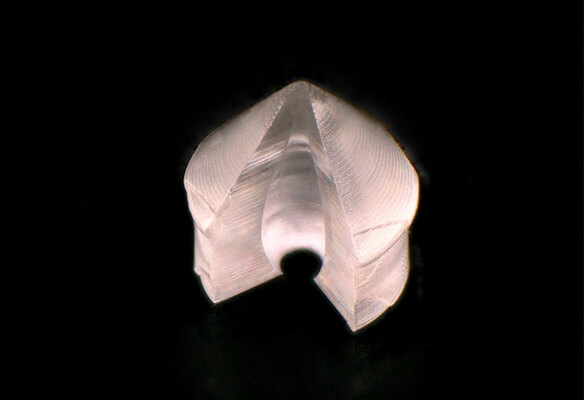

Microchannel

Undercut nozzles on the inside, which are difficult to create by cutting.

05

Biomimetics

Ants that are shaped from its CT data.

06

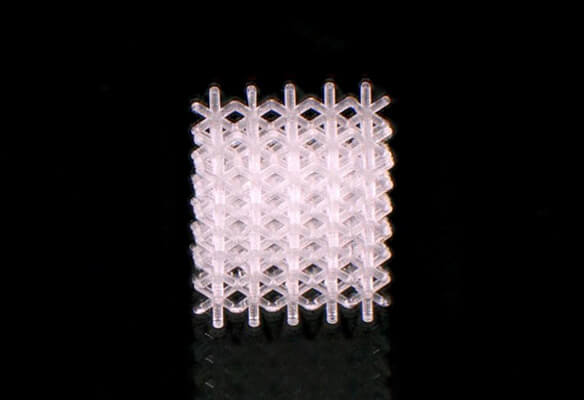

Photonics

Submicron lattice structure

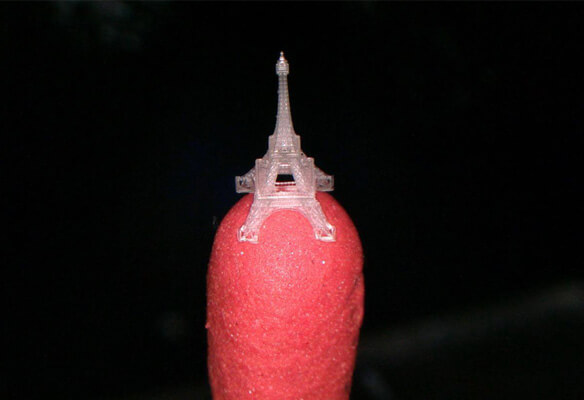

07

Micro rapid prototyping

The Eiffel Tower standing on a matchstick head.

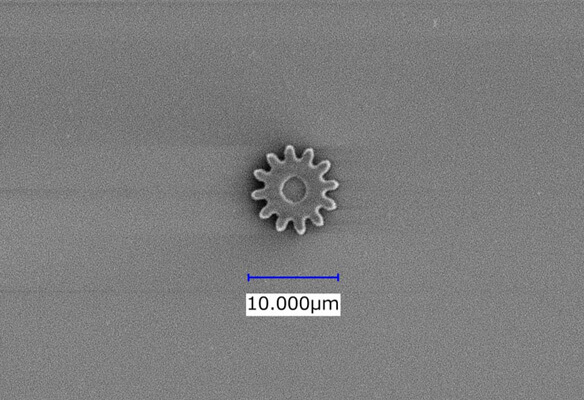

08

Micro rapid prototyping

Spur gears with a circumscribed circle of 10 micrometers

09

Micro rapid prototyping

Plated Japanese battleship Yamato, which is about the width of a human hair. (Method: sputtering/ Material: platinum)

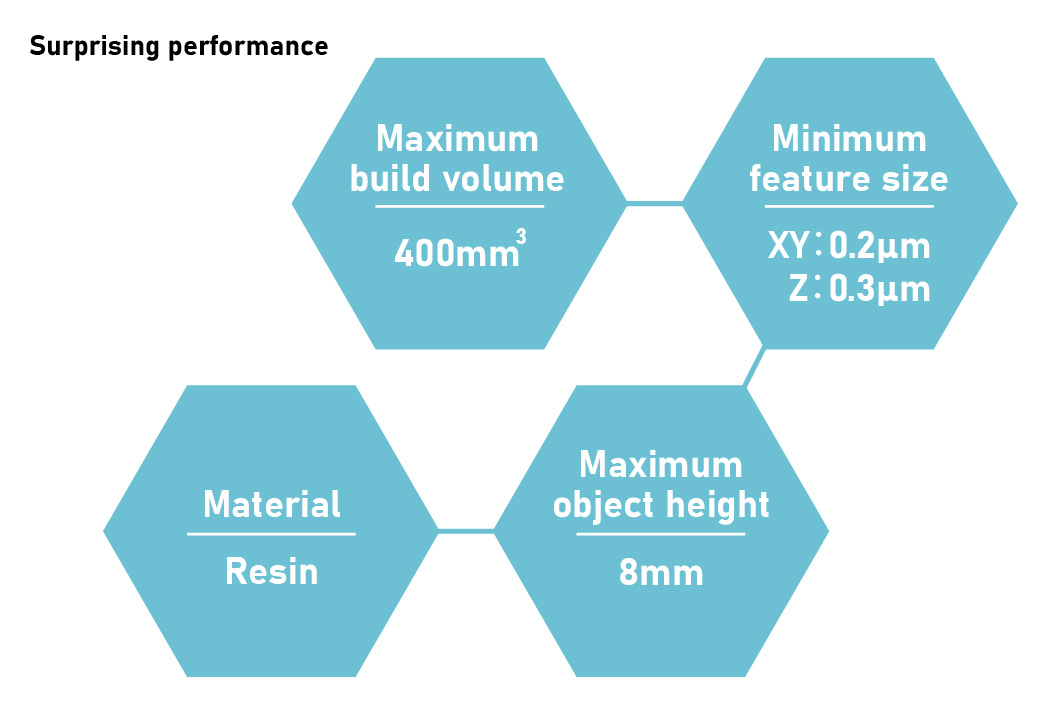

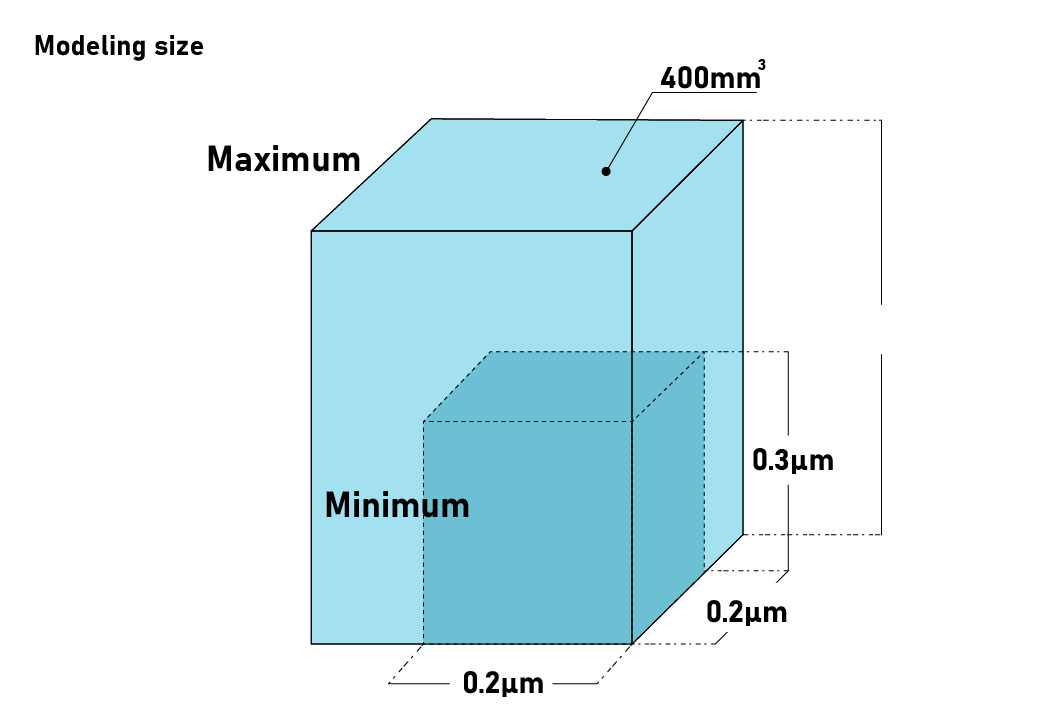

Submicron 3D Printing Specification

| Printing mode | Substrate | Heat resistance | Minimum size | Maximum size | |||

|---|---|---|---|---|---|---|---|

| Voxel (XY direction) | Layer thickness (Z direction) | Voxel (XY direction) | Layer thickness (Z direction) | Maximum print volume | |||

| LF | Silicon | IP-Dip 371℃ | 1.2㎛ | 5㎛ | 15mm | 8mm | 400m㎥ |

| MF | ITO | IP-S 300℃ | 0.6㎛ | 1㎛ | 10mm | 3mm | 50m㎥ |

| SF | Silica | IP-Q 242℃ | 0.2㎛ | 0.3㎛ | 10mm | 3mm | 0.1m㎥ |

Service Flow

STEP 01

Inquiry

Please contact us about your request and details by phone or email.

STEP 02

3D Data Collection

Sketch and original that you want to make fine size are available.

STEP 03

Quotation

Please acknowledge the costs before completing your order.

STEP 04

Production

The production period would be different depending on the shape.

STEP 05

Delivery

Since the micro product is delicate, please handle it with great care.

Option

Dry plating (Material: platinum, etc. )

Option

Microphotography

Click here for estimates and inquiries

Hours of operation: 8:30 a.m. - 5:30 p.m.

(excluding Saturdays, Sundays, and national holidays)

(excluding Saturdays, Sundays, and national holidays)

Click here for the inquiry form

Catalog Download

Collaboration Between University and Company

Great Partnership

We have been promoting collaborative research on the “Nanoscribe system” with the Kyoto University of Advanced Science. Currently, the submicron structures formed by this system are made of resin, but the research of metallic submicron products by using casting technology has been carried out for the future.